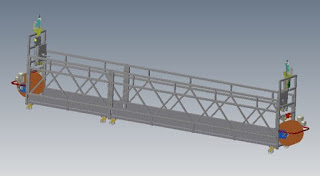

HANGER WITHOUT PULLEY SCAFFOLDING

GENERAL FEATURES

- Galvanized work platform with detachable and 3 mm trench base at 800, 700, 600, 400, 300, 200 * 66 * 110 cm

- Efficient use as 2m 4m and 6m thanks to removable steel structure.

- 2 pieces 40 * 40 * 3 mm galvanized side doors and block stop safety locks for security.

- 2 units 1,1 kW WAT brand 380 volt 50-60 Hz Electric motor, production-driven climbing system with special Aluminum body working with Temporiti (Italy) cooled brake and reducer system connected to the engine.

- The vertical speed of the platform is ̴12cm / sec. And average ~ 7m / min. Corresponds.

- There are 2 block safety locks for safety.

- Central control panel with one central 380 volt thermal protection (Moeller automation material).

- 50m 5x2,5 power cable is provided.

- 4 drunk type polyamide wheels and 2 polyurethane front walkers.

- The safe lifting capacity for ASM 50 model electric suspension scaffolds is 500 kg for 6 m platform.

Climbing System:

- In the climbing system, two automatic rope walking mechanisms compatible with 8mm rope are used.

- The climbing mechanism consists entirely of steel evenings and the risk of deformation and failure is minimized.

The components of this system are:

- 2 pieces 1,1 KW Wat brand 380 volt electric motor,

- Temporiti (Italy) brand air cooled brake with 2 motors

- 2 Type 1/40 bond type 63 Type (35 rpm) STM reducer

- It consists of 2 special steel body and special rope walking system.

- The vertical movement speed will be 12 cm / s (7 m / min).

- It is possible to go down manually when the power is cut off.

- The engines will be protected to prevent them from being exposed to rain.

Electrical Equipment, Panel and Control:

- It will be with Control Cable.

- There will be an automation panel in 1 basket.

- All movements of the machine will be controlled by the control system in the basket.

- Thermal motor protection switches and other materials that protect the system against phase cuts or engine disturbances will be in the electric cabinet.

- The energy required for the work basket will be obtained by means of the cable to be lowered from above.

SAFETY ASSEMBLY

- In case of the breakage of the ropes entering the automatic winding, there will be 2 block stop mechanisms entering the circuit.

- The basket top switch will be used to prevent an obstacle from hitting the basket during climbing.

- It is possible to manually lower the work basket when the power is cut off.

PAINT, GALVANIZE

- All moving steel parts of the machine will be electro galvanized.

- The other parts of the machine will be painted acrylic on industrial undercoat.

HANGER WITH PULLEY SCAFFOLDING

GENERAL FEATURES

- Galvanized work platform with detachable and 3 mm trench base at 800, 700, 600, 400, 300, 200 * 66 * 110 cm

- Efficient use as 2m 4m and 6m thanks to removable steel structure.

- 2 pieces 40 * 40 * 3 mm galvanized side doors and block stop safety locks for security.

- 2 units 1,1 kW WAT brand 380 volt 50-60 Hz Electric motor, production-driven climbing system with special Aluminum body working with Temporiti (Italy) cooled brake and reducer system connected to the engine.

- The vertical speed of the platform is ̴12cm / sec. And average ~ 7m / min. Corresponds.

- There are 2 block safety locks for safety.

- Central control panel with one central 380 volt thermal protection (Moeller automation material).

- 50m 5x2,5 power cable is provided.

- 4 drunk type polyamide wheels and 2 polyurethane front walkers.

- The safe lifting capacity for ASM 50 model electric suspension scaffolds is 500 kg for 6 m platform.

Climbing System:

- In the climbing system, two automatic rope walking mechanisms compatible with 8mm rope are used.

- The climbing mechanism consists entirely of steel evenings and the risk of deformation and failure is minimized.

The components of this system are:

- 2 pieces 1,1 KW Wat brand 380 volt electric motor,

- Temporiti (Italy) brand air cooled brake with 2 motors

- 2 Type 1/40 bond type 63 Type (35 rpm) STM or POLAT reducer

- It consists of 2 special steel body and special rope walking system.

- The vertical movement speed will be 12 cm / s (7 m / min).

- It is possible to go down manually when the power is cut off.

- The engines will be protected to prevent them from being exposed to rain.

Rope Collection System:

- In order to prevent the ropes from hanging down in the basket, there are 2 motorized rope picking rolls wrapped around the automatic rope pulling ropes and safety ropes.

- This system will work with 2 pieces of 0,25 kW motor and 50 types of regulators.

- The engines will be protected to prevent them from being exposed to rain.

Electrical Equipment, Panel and Control:

- It will be with Control Cable.

- There will be an automation panel in 1 basket.

- All movements of the machine will be controlled by the control system in the basket.

- Thermal motor protection switches and other materials that protect the system against phase cuts or engine disturbances will be in the electric cabinet.

- The energy required for the work basket will be obtained by means of the cable to be lowered from above.

SAFETY ASSEMBLY

- In case of the breakage of the ropes entering the automatic winding, there will be 2 block stop mechanisms entering the circuit.

- The basket top switch will be used to prevent an obstacle from hitting the basket during climbing.

- It is possible to manually lower the work basket when the power is cut off.

PAINT, GALVANIZE

- All moving steel parts of the machine will be electro galvanized.

- The other parts of the machine will be painted acrylic on industrial undercoat.

You can call us at 05557176091 to get in touch immediately.